The design of slewing bearings

Advanced calculation techniques attuned to slewing bearings guarantee an economic and safe dimensioning of load transmitting and of components in which deformation is a critical factor. This new method allows a highly economical solution as well as from the mechanics point of view a very realistic analysis of the overall system of slewing bearing and companion structure.

The production of rings

Then follows the production of the ring forgings in the Dortmund plant.

The production of slewing bearings

After that, the finish-rolled ring is transported from Dortmund to the Lippstadt plant for further machining and treatment.

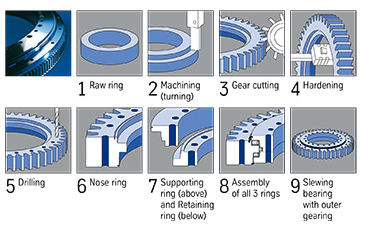

Slewing bearing - Manufacturing process

1- Raw ring

2- Machining (Turntable)

3- Gear cutting

4- Hardening

5- Drilling

6- Nose ring

7- Supporting ring (above) and Retaining ring (below)

8- Assembly of all 3 rings

9- Slewing bearing with outer gearing

needle roller manufacturers I have read all the comments and suggestions posted by the visitors for this article are very fine,We will wait for your next article so only.Thanks!

ReplyDelete